Turning Waste into Resource: The Power of PP Recycling

Turning Waste into Resource: The Power of PP Recycling

Blog Article

As sustainability becomes a vital focus world wide, the highlight is on how industries may reduce environmental impacts. Polypropylene (PP), one of the very most generally applied parts, has received significant attention due to its possible in the circular economy. With growing concerns about plastic waste, PP recycle alternatives are emerging as a encouraging avenue for reaching sustainability goals and lowering environmental footprints.

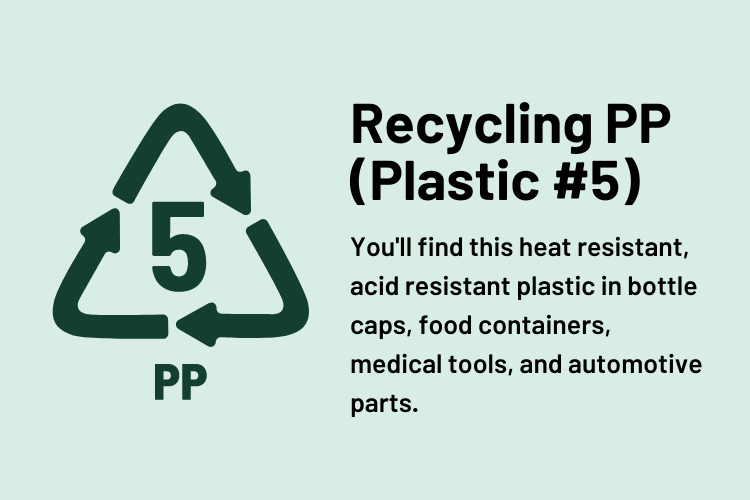

Polypropylene is widely used across different industries, from presentation to automotive elements, because of its versatility, energy, and cost-effectiveness. But, the persistence of PP in landfills and oceans poses a significant environmental challenge. Fortunately, improvements in recycling systems are giving new possibilities to sell PP more proficiently and effectively.

One of the most substantial developments in PP recycling could be the upsurge in physical recycling processes. Technical recycling requires wearing down plastic waste into little particles, which will then be reprocessed in to new products. This approach supplies a more energy-efficient alternative compared to old-fashioned plastic production. PP could be recycled multiple situations, lowering the necessity for virgin substance removal and reducing the general carbon footprint.

As well as technical recycling, chemical recycling systems are gaining traction. Chemical recycling requires breaking down plastics into their base compounds, which may be recycled to create new plastic products. This approach permits the recycling of contaminated or mixed plastic spend that would usually be non-recyclable through conventional methods. As substance recycling systems improve, they could revolutionize just how PP is processed and recycled, rendering it a vital player in the continuing future of plastic waste management.

The raising concentrate on PP recycling can also be driving inventions in item design. Businesses are creating PP services and products that are easier to sell by utilizing monomaterial packaging, removing hazardous ingredients, and promoting designs that facilitate the recycling process. Effort across industries is imperative to ensuring that PP items are recyclable right away and could be effectively processed at the end of the living cycle.

More over, consumer consciousness and conduct play a significant position in the accomplishment of PP recycling. With rising need for sustainable services and products, more persons and organizations are using steps to ensure that PP spend is removed correctly. Education campaigns and incentive programs can encourage greater recycling techniques and support shut the trap on PP waste.

Looking forward, PP recycling alternatives are positioned to be at the forefront of sustainable waste management. As systems improve and industries undertake more rounded practices, PP may continue to be a valuable reference, driving both environmental and financial benefits. The future of sustainability hinges on improvements in recycling, and PP recycling alternatives can certainly perform a pivotal position in surrounding this future. Report this page